Understanding the Art of Welding: How to Avoid Undercut Welding Issues for Flawless Manufacture Results

Efficiency and precision are critical on the planet of welding, where even the tiniest imperfection can jeopardize the architectural integrity of a made item. One common challenge that welders face is damaging, an issue that can weaken a weld joint and lead to costly rework. By understanding the root creates of undercut welding and executing effective methods to stop it, welders can raise their craft to brand-new degrees of quality (Preventing weld undercut). In the search of remarkable manufacture results, understanding the art of welding to avoid undercut issues is not just a skill however a need for those aiming for excellence in their work.

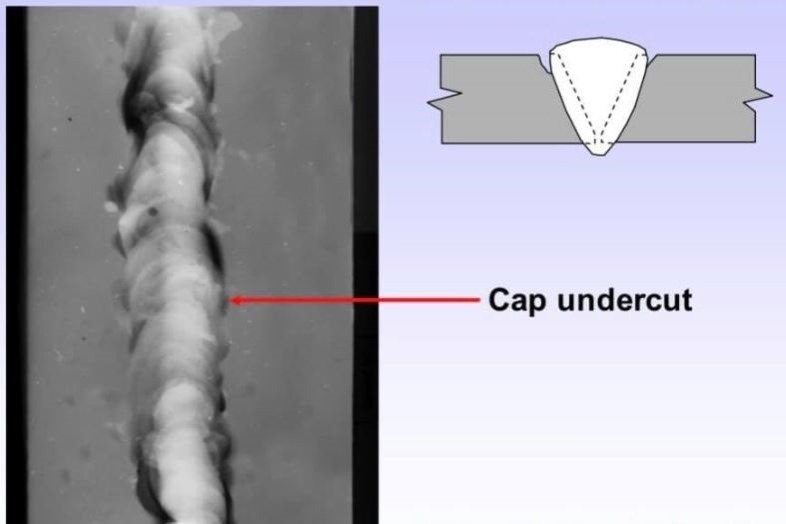

Comprehending Undercut Welding

To avoid undercut welding, welders must guarantee correct welding specifications, such as changing the current, voltage, travel speed, and maintaining the correct electrode angle. By recognizing the causes of undercut welding and implementing preventive steps, welders can accomplish premium, structurally sound welds.

Reasons For Undercut in Welding

Understanding the elements that add to undercut in welding is vital for welders to generate top quality, structurally sound welds. When the weld metal does not appropriately load the groove formed between the base steel and the formerly deposited weld metal, undercutting happens. Several factors can lead to undercut in welding. One typical cause is too much warmth input. Welding at high temperatures for prolonged durations can lead to the base steel melting even more than wanted, resulting in undercut. Inadequate welding incorrect or existing welding speed can also contribute to damage. Inadequate current might not provide adequate warm to melt the base and filler metals effectively, while extreme speed can prevent appropriate fusion, creating undercut. In addition, incorrect electrode angles or inaccurate lantern adjustment techniques can develop locations of low weld metal deposition, promoting undercut. Recognizing these causes and executing proper welding techniques can aid stop undercutting problems, making certain durable and solid welds.

Techniques to stop Undercutting

To reduce the threat of undercutting in welding, welders can employ calculated welding techniques targeted at improving the high quality and honesty of the weld joints. One effective approach is to readjust the welding specifications, such as voltage, present, and travel speed, to guarantee appropriate heat input and deposition. Maintaining a suitable electrode angle and making sure constant travel speed can also help avoid undercut. Additionally, using the appropriate welding technique for the certain joint setup, such as weave or stringer beads, can add to lowering undercutting. Preventing weld undercut.

Furthermore, correct joint prep work, consisting read the article of making sure clean base products without impurities and utilizing the proper welding consumables, is essential in protecting against undercut defects. Using back-step welding methods and regulating the weld bead account can likewise assist disperse heat evenly and decrease the threat of undercut. Regular evaluation of the weld joint throughout and after welding, in addition to carrying out top quality guarantee actions, can help in discovering Extra resources and attending to undercutting issues immediately. By applying these methods faithfully, welders can achieve flawless manufacture results with minimal undercut issues.

Significance of Proper Welding Criteria

Choosing and preserving appropriate welding specifications is vital for attaining successful welds with very little flaws. Welding specifications describe variables such as voltage, current, take a trip speed, electrode angle, and securing gas circulation price that directly influence the welding procedure. These specifications must be carefully adjusted based on the sort of material being bonded, its thickness, and the welding technique used.

Proper welding specifications make certain the appropriate quantity of warmth is related to melt the base steels and filler product consistently. If the specifications are established too expensive, it can bring about excessive heat input, causing distortion, spatter, or burn-through. On the other hand, if the specifications are too low, insufficient combination, absence of infiltration, or damaging may occur.

Top Quality Assurance in Welding Operations

Verdict

Finally, mastering the art of welding calls for an extensive understanding of undercut welding, its causes, and techniques to avoid it. By making certain appropriate welding specifications and executing quality control techniques, flawless construction outcomes can be attained. It is vital for welders to constantly pursue quality in their welding operations to prevent undercut problems and produce premium welds.

Undercut welding, an usual defect in welding procedures, occurs when the weld metal does not appropriately fill up the groove and leaves More Bonuses a groove or depression along the welded joint.To avoid undercut welding, welders ought to ensure proper welding criteria, such as readjusting the current, voltage, travel speed, and keeping the appropriate electrode angle. Insufficient welding incorrect or present welding rate can also contribute to undercut.To mitigate the threat of undercutting in welding, welders can utilize critical welding methods intended at improving the top quality and stability of the weld joints.In verdict, mastering the art of welding needs a comprehensive understanding of undercut welding, its reasons, and techniques to prevent it.